How To Install Chain Wire Fence

Chain Link Fence Installation Manual

Shop: Chain Link Fence | Fence Tools

Read More than: How to Install Chain Link Fence (PDF) | Chain Link Installation Tutorial (PDF) | Chain Link Fence Arrangement Overview

Jump to Preferred Section:

Before You Begin:

Stride i - Obtain necessary zoning and building permits. There may exist local zoning or deed restrictions pertaining to height and type of fence and/ or gate. Check out property line setback requirements. Discover surveyors pins if the fence is to be located about property lines or have the lot surveyed.

Step ii - Measure out argue footage and locate gate placement.

Step three - Call 811 before you dig. Notify your local or country utilities protection service to locate potential buried utilities. There is usually no charge to locate utilities, however a hefty charge could exisit for repairing buried utility lines, not to mention a potential injury to yourself.

Footstep 4 - Purchase your Chain Link Debate from HooverFence.com.

Tools Needed For Installation:

Postal service Setting/Layout Tools:

Chain Link Stretching Tools:

Unwrapping and Inspecting Fence Shipment:

Prepare for your HooverFence.com argue delivery. Chain link contend orders can arrive on small and large trucks, covered trailers and flatbed debate trucks. Forklifts are commonly not required, nonetheless exist prepared to manus unload argue tubing, rolls of concatenation link, bags and boxes of chain link fittings.

The first thing we recommend is that you carefully unwrap and audit your shipment to verify that you have all of your materials. Make sure to get over and read all of the instructions at this time. While the installation of the fence is relatively piece of cake, this online instruction guide should eliminate any guesswork. If you accept any questions or problems installing the fence, delight requite u.s.a. a phone call.

Read More: Shipping Policy.

Found Fence Lines:

Y'all will establish the futurity debate line by using the stakes and string to stake out the area to be enclosed.

Footstep one - Bulldoze stakes a foot or two away from where you want corner and stop posts to exist located; this volition allow y'all to drill/ dig holes without obstructions. It may too allow you to 'drop' the cord while excavating for argue post holes. Be careful not to crash-land or move stakes. If y'all remove the string to excavate holes, have care to restretch the string line back the way it was prior to removing.

Step ii - Stretch masonry guide cord tight betwixt these stakes. This cord will represent the location of the fence and serve equally a guide cord as you lot set posts. Posts will be set in concrete or driven i/viii-1/four" from string line.

Footstep iii - Intermediate stakes may be required for longer stretches of contend. Exist certain to pull cord taut as string which sags or moves with the wind volition cause posts to exist prepare incorrectly. Keep in heed, the fence tin can only exist every bit straight every bit the guide string.

Pace 4 - Locate gate posts first and mark their location with upside downwardly mail hole mark paint. Side by side measure each stretch of fence. Concatenation link fence posts are typically spaced a maximum of 10 feet apart. For aesthetic reasons, infinite posts evenly, but do NOT exceed ten feet between posts. If you program on installing privacy slats or some other type of material that will increase wind load, consider using 8' or vi' post spacing. Also consider upgrading the framework, i.e. posts and rail to a larger bore and thicker wall thickness. Heavier chain link framework such as HF20 and/ or HF40 are excellent choices for apply with chain link fences with aluminum diagonal or PVC privacy slats or privacy screening.

Marking Pigment

Post Location

Creating Square Corners Using the iii-4-v Method:

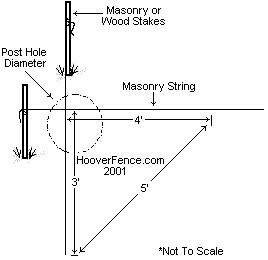

Footstep ane - Stretch cord downward the two next sides equally shown in cartoon.

Step 2 - Measure and make mark iii' downwards on 1 line.

Stride 3 - Measure out and make marker four' down on other line.

Footstep 4 - Measure diagonally between the two marks and accommodate lines to reach v'.

Note: For greater accuracy, use measurements in multiples of iii-iv-5, such every bit half-dozen-viii-10, etc.

Setting Posts:

Typical Post Layout

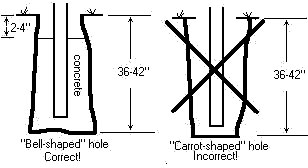

Correct Post Hole Shape

Step i - Depending on the geographical location, fence height, and fencing materials used, post hole size may vary. In general for residential chain link fences, dig holes six" in diameter by xxx" deep (or below frost line in your surface area). Another dominion of pollex is to dig the holes 3 times the bore of the post, i.e. a 2" diameter postal service would require a half dozen" diameter hole, and put one third of the height of fence that's above basis - in the ground. Typically gate post holes are dug larger in bore and deeper to withstand the additional stress of a moving gate. The guide string may exist removed temporarily prior to excavating to forestall cutting it. Be sure to supervene upon it every bit it was originally stretched.

Chain link debate posts holes tin exist dug by hand with post pigsty diggers and spud bars, minor gas powered augers, or skid steers with hydraulic augers. Size your auger bit accordingly to the peak and grade of debate materials to exist installed.

Holes next to buildings often must be dug by hand. Accept caution as drain pipes and other utilities can be located about foundations.

Some obstructions such every bit the one higher up tin be hard to deal with. A postal service may be bent in this case to miss the pipe. Measure the depth of the bend first.

Notice how the postal service remains tight to the house, yet is still dug to depth with a sufficient concrete footer.

Stride 2 - Restretch guide string and cheque holes for accuracy visually and/or by placing a post in the pigsty and plumbing in all directions. If the pigsty needs 'shaved' or moved, do it at present. If holes are shallow considering y'all striking an object you lot can't remove, 'bell' the hole at the bottom. To 'bell' a hole, use a mail service hole digger and/ or potato bar to make the bottom of the pigsty larger than the top. This further anchors the physical footer which will support your argue. 'Belling' will compensate for holes as shallow every bit xviii" deep. If necessary, move the hole slightly to miss any obstructions. This will change your mail service spacing. However, there is no damage in the case of line posts. If you must motion information technology more than than a couple of anxiety, consider installing an extra post midway in the enlarged infinite. Other means of dealing with obstructions include bending posts below ground and welding plates on to posts to secure to large rocks.

Cheque pigsty location prior to filling with physical mix. The hole should non be centered perfectly under string line; it should be beginning slightly and then that the post will be centered in the concrete footer. If necessary put post in empty hole and check plumb with a level. The post should be plumb to the cord with approx. 1/8-i/4" clearance. If not, fence post hole will need 'shaved'.

Once fence posts holes have been dug and cleaned out, check that each and every hole is in the correct spot. If you cannot tell visibly, place mail in hole and plumb mail. Mail service needs to sit plumb and be placed 1/8"-1/4" off the cord line.

Debate Tip: Be certain to dig fence post holes to the proper depth and diameter for your region. Northern regions take frost depths deeper than the southern part of the country. 30-36" deep physical footers suffice for well-nigh fence installations.

Stride 3 - Mix concrete with water using pre-mixed bag. Go piece of cake on the water. Mix should look like thick gray mud, not like Mom'southward watered-down chili. If it doesn't pile upward on the shovel, it's besides thin; add more than mix to dry out it up. If you are mixing from scratch using amass like gravel, limestone or sea shells, concrete sand and Portland cement, mix 3 to four parts (shovels) of aggregate to 2 parts sand and 1 part cement.

Smaller debate projects are often prepare using a premixed bagged concrete. Ofttimes sold at do-it-yourself stores, forty, 60, and 80 pound numberless are commonly readily available for your fence projection. Figure your fence mail service concrete requirements by using HooverFence.com'south physical calculator.

Premixed bags of concrete may exist mixed by hand in a wheelbarrow with a shovel, or with a gas powered, or electric powered cement mixer. Mix concrete to a 'thick milk shake' like consistency. Do not mix also moisture, or the soup-like texture will cause posts to sink, or the concrete may not set at all.

For small chain link fence jobs where the job can be set and stretched in the same twenty-four hours, using a small amount of Quik Rok, or other brand of fast setting hydraulic cement with regular premix cement can save fourth dimension and an extra trip to the jobsite.

Quik Rok, fast setting hydraulic cement is available in 5 gallon pails and is a powder similar material that can be used alone for small holes (core drilling in cement). Y'all can also mix most a shovel full of this baking flour similar material in with a wheelbarrow total of regular cement.

Fence Tip: Some fence spec jobs require physical footers to be poured to the meridian, capped and trowelled. Use a pointing trowel for improve advent.

Footstep iv - Mark mail class marker. Stop, corner and gate posts should exist marked at the height of the contend plus i inch; 49" for a iv' fence, 61" for a 5' fence, etc. Mark intermediate or line posts at height of the debate minus 3 inches; 45" for 4' debate, 57" for v' fence, etc. When y'all add your line post cap and top rail, the pinnacle will exist accurate. Grade marks represent the bottom of the argue and are essential in setting posts to the correct depth. If y'all coffin the post hiding the form mark past 1", you will need to trench to bury the fence here. If your grade mark is above footing by 3", your fence volition exist off the ground by three inches and you better plan to cut it off later or fill nether the contend if a tight fit is necessary.

For chain link fences, line posts (intermediate posts) should exist marked with a grade mark at 3" less than the meridian of argue beingness installed. Here a 6' loftier fence is being installed. Line posts are marked at five'-9".

Fence Tip: Vinyl coated chain link fabric is more elastic than galvanized mesh and can 'shrink' slightly when stretched. Subtract an additional 1/2" if yous're setting posts for a fence with vinyl coated cloth.

For chain link fences, terminal posts, i.due east. end posts, corner posts, and gate posts, are marked at 1" more than the height of fence being installed. For a six' high chain link fence, mark posts at half dozen'-1".

Contend Tip: Place a spare slice of tubing, or mail that has non nonetheless been attack the top of gate posts later setting and level these posts to one another. Gates are usually perfectly square.

Step five - Make full holes with wet cement. Do non fill too many and risk having the concrete cure earlier you can 'stick' your posts. Do not fill holes to the the top with physical, leave the concrete down 3-four". Filling the hole completely with cement is a common fault. If this is washed, water will collect under this 'lip' of concrete. When information technology freezes, the ground will literally squeeze the concrete footer and 'heave' the postal service up, much like squeezing a tube of toothpaste.

Once argue post holes accept been dug and cleaned out (exist sure to make clean out postal service holes of loose dirt and droppings), shovel cement into holes until they are near total. Leave cement down from the ground surface (grade) approx. 3". Holes should as well be larger in diameter at the lesser than at summit, 'bell-shaped'. Holes shaped like a carrot can boost prematurely.

Fence mail holes can exist filled practically every bit fast as the cement batches can be mixed and poured. Often some other person can follow the person filling the holes and 'stick' the debate posts. 'Sticking' fence posts just ways putting the posts in a pigsty that has already been filled with cement, plumb and tight to the cord line.

Fill post holes with concrete mix. Practice non fill up holes completely. This may crusade posts to heave prematurely.

Step half-dozen - Stick Posts. Most chain link posts can be installed by actually pouring the cement in the hole first and then 'sticking' the post in the wet cement. Just push the post into the cement mix in the center of the hole. Set last posts as tight to the string as possible without touching the string. Ready line posts approx. 1/8"-1/4" off string. This will account for the differences in fence post diameters. Another manner of setting posts is for i person to hold the post plumb to the string line while some other shovels concrete mix around the post. The first method explained is actually easier, a more efficient manner of setting argue posts, and assures in that location is concrete around the post, under it, as well as in information technology.

Chain link fence posts should be 'stuck' down to their respective grade marks and plumbed with guide string. Backfill with loose dirt and step gently on clay surrounding posts to aid hold them also meridian. If posts sink on you lot, concrete is too wet, or holes take filled with water.

You tin and should put your posts in their holes and bank check them to the string line with a level if you're not certain mail holes have been dug in the correct spot. It can be very frustrating if holes have not been checked for accuracy, then filled with cement. You'll find yourself trying to stick posts into the clay surround the dug hole, simply buried in cement. If this happens, pull post, redig pigsty, and try to catch up with your crew!

On sloped terrain, it is sometimes necessary to fix posts intentionally high, with grade marks exposed. The concatenation link height is actually taller when measuring diagonally. If in doubt, mensurate square with course to help gauge your finished height of the material. Chain link is remarkably versatile and tin can be installed on whatsoever terrain.

Fence Tip: When in doubt, leave post high and cut off later. This is much easier than trying to extend the height of a chain link fence post!

After chain link fence posts take been 'stuck', check cement level is correct. You should put more cement in if physical levels are besides low.

Argue Tip: Avert pushing away your guide string to fill holes with cement if some other is using information technology to 'stick' posts!

Set posts to the depth of the grade mark first. Exist certain to fix fence posts tight to any buildings if animal containment is important.

Step 7 - After setting each mail service to grade, backfill with clay and stride on the backfill to hold the postal service to pinnacle. Echo for all posts in this length of fence.

Later 'sticking' post in hole with concrete mix, backfill with loose dirt. Plumb post while stepping on clay around post. This volition help hold the postal service plumb in the hole.

Stride 8 - Sight posts. To 'sight' in posts, stand at end of length of fence and wait across the tops of the posts. Accommodate heights of posts equally necessary to account for gradual slopes and changes in grade. The goal is to accept shine transitions between posts and to avert sharp changes. This is easiest for two people to reach: 1 persons sights posts while the other adjusts and checks for mail plumb. Be certain to cheque plumb on each post after adjusting and spotter the grade mark as noted higher up.

In one case posts have been set to grade, sight across the tops of the gear up posts and raise or lower them slightly to smooth out the top of the fence. Keep in mind, if you coffin your grade mark slightly on one or more posts, plan to trench this same corporeality for the chain link cloth. The grade marks represent the bottom of the chain link fence. If your grade mark is 4" off the ground, so will be your fence and y'all may be filling underneath.

Notation: Although near fences are simply installed to form, or flow with the contour of the country, some applications would be ameliorate set perfectly level, i.e. tennis court enclosures, basketball courtroom enclosures, baseball and softball backstops, sideline fences, and homerun fences. If excavating, grading, or cobblestone/ physical is to be poured later, or is already in identify, the fence may need to exist installed perfectly level. If this is the instance, sighting with grade marks, using a string line with a level, or a transom volition help immensely.

Stride 9 - Install gate posts with the exact opening size as recommended by gate supplier or manufacturer. The opening size is the distance betwixt the two gate posts, within to inside. If possible make the tops of gate posts level to each other by placing a post beyond the tops of the posts and checking with a level. If the basis slopes off sharply under the gate, set the gate posts to course. It won't look proper to brand them level.

Step x - Let physical cure for at to the lowest degree 24 hours prior to continuing piece of work.

Installing Mail service Fittings:

Typical Terminal Post Fitting Diagram

View of lesser brace band for lesser wire, and 4 tension bands for a 5' high chain link debate. View is from the within of debate. Notice tension bands are offset so that the flat side is facing out.

End post with brace band bolted with a rail end cup. All nuts confront towards the within of the chain link contend enclosure.

Combo runway end cups (with holes in them for truss rods) may exist used for peak rails, mid rail, and bottom rail to connect fence rail to terminal posts.

Proper installation of runway cease cups and brace bands for a concatenation link debate corner mail service. Detect one points up, the other down. This allows top rail to remain even at such a junction.

One concatenation link caryatid band with nut and commodities and 5 tension bands are used for a vi' high concatenation link debate.

Here spinous wire artillery are used every bit loop caps for a 6' high plus 1' of barbed wire chain link fence.

Loop caps simply slide on top of posts. Top runway slides through horizontally.

Step one - Place tension bands on end and corner posts.

Footstep two - Quantity of tension bands per hook-upward = pinnacle of contend minus ane; minimum of 3. For example, a 4' loftier chain link fence requires three tension bands per claw-up.

Stride 3 - A hook-upwardly is each connectedness of chain link to an end or corner mail service. Stop posts have one hook-upwardly; corner posts have two claw-ups.

Pace 4 - Place 1 brace band on starting time to utilize if lesser tension wire will be installed. This fitting requires one 5/sixteen" 10 1-ane/4" standard contend commodities and nut. Install nut and bolt loosely.

Step 5 - Next, install tension bands. The tension bands are offset. The get-go (flat side) faces 'out', the same side as the concatenation link fabric will be installed. This is unremarkably the outside of the enclosed surface area. Do non install nuts and bolts on these.

Step half-dozen - Identify one brace band per hook-up over the tension bands . This plumbing equipment requires one rail end loving cup, ane commodities and nut. This ring and cup will exist used for the top track. Tighten with a ratchet and socket.

Step 7 - The track end cup is beginning also. This outset tin be up or down on an end post. Regardless of if y'all choose to position the cup upwardly or down, be consequent. On a corner, since two sets of brace bands and rail end cups must share the same space, the lesser rail finish cup is to exist offset upwardly and the bottom rails terminate cup is to be offset downward. This enables the ii cups to exist level to each other, so your acme rail can be inserted into the cups and be level to each other.

Stride 8 - Typically all nuts are kept on the inside of the fence; this prevents someone on the outside from removing the nuts easily. For high security applications, the threads on the bolt may be 'peened' to forestall easy removal. This can be washed by using a hammer and chisel and distorting the threads on the bolt and then the nut tin can not be removed.

Step 9 - Place mail caps on posts. The stop and corner postal service caps are simple. There is but one manner to install them. The loop caps, as they are chosen, are offset, if you look at them carefully. The offset side faces the outside of the enclosure; the same side as the chain link will be installed. Concatenation link loops caps are available in aluminum, or pressed steel with a galvanized finish. If barbed wire is to be installed, substitute barbarms in lieu of standard chain link fence loop caps. Concatenation link 3-Wire barbarms are available in equally 45 degree barbarm, directly vertical barbarm, and an adjustable barbarm. Nosotros also carry a half-dozen-wire barbarm.

Argue Tip: You may 'pre-squeeze' bands subsequently they take been slid on to posts. This is washed by essentially pinching brace bands and tension bands with a pair of contend pliers. Brand sure y'all keep commodities holes lined upwards as you lot clasp the bands shut. Subsequently, when you lot are connecting the scroll of chain link to the terminal posts, you volition be thankful bands take been pre-squeezed equally they will now allow you to fit your 5/16" x one-1/four" nut and bolt through and thread the contend nut much easier.

Installing Top/Bottom Rail:

Typical Top Rail Associates Diagram

Loop caps simply slide on top of posts. Top rail slides through horizontally.

Offset of loop cap faces 'out'. This helps keep the framework affluent to the material side of the concatenation link fence.

Elevation rail sits on superlative of line posts and runs 'to' terminal posts.

one-iii/8" and 1-5/8", mutual sizes for top rails, are available swedged or obviously end. Plain end summit track requires sleeves equally shown above.

Chain link argue superlative rail with plain ends will require top track sleeves. HF40 heavy industrial top rail is only available with plain ends.

HF20 top rail and lighter is available with a swedged end, a sleeve will non be required.

A hacksaw, chop saw, sawzall, pipe cutter, or portable band saw are used to cut meridian rail.

Chain link fence with top track finished. Once framed, chain link textile may be stretched.

Step 1 - Slide top rail through a couple loop caps and barrel end firmly into rail end cup. Adjust height of rail end cup if necessary. Tighten rail cease cup firmly.

Step 2 - Some top track has a 'swedged' cease, which tapers downward so it will fit into another slice of rail. Fit the not-swedged end into the rail end cup at the terminate or corner mail service.

Pace 3 - Add sections of rail, sliding each non-swedged terminate into a swedged stop. Be certain to push button runway toward your starting time indicate to 'seat' them all the fashion into each other. Button firmly. If the acme rail has no swedged cease so you lot need a 'sleeve' that acts as a coupling.

Step 4 - Add additional top rail until you lot attain the side by side terminal postal service, i.eastward. end, corner, gate post.

Step 5 - Cutting excess rail off with hack saw or piping cutter. Marking the cut-off point carefully so the track will fit snugly into the rail finish cup. Any slack in your entire length of rail will allow the chain link, when stretched tight, to pull the cease posts in towards each other. Tip: Each piece of rail should be supported by 2 posts. Practise not cut runway so that a seam volition exist in-betwixt the last line mail service and concluding post. This signal will exist weak and tend to sag.

Step 6 - Install top rail in all stretches of fence. At this indicate, visually check the elevation of line posts once pinnacle rails is installed. If a postal service is as well high, remove track and trim equally necessary.

Fence Tip: If a mail is one/4" too short you may also cut a sliver of pipe, the same diameter size every bit the line post and slip it under the loop cap.

NOTE: Industrial chore sites occasionally substitute a tiptop tension wire in lieu of top track to cut down on price. If this is the example, you will demand to brace and truss the terminal posts. Read More: How to Brace and Truss Chain Link Fence.

Installing Tension Wire:

Figure 1

Figure 2

Figure three

Figure 4

Tension wire may be installed at the top and/or bottom of a chain link debate. Top tension wire helps cut down on cost when used in lieu of top runway. Lesser wire helps deter animals from digging and pushing the bottom of the fabric out. It is frequently used with vinyl coated chain link as this tends to exist more than elastic in nature. Both types of wire are attached to the chain link, in one case stretched, with hog rings. It is easiest to install when one person holds the whorl of wire upright while the other 'walks' the loose end to the other end of the fence. The next step is to hook up the loose end to the terminal post using a caryatid ring and nut and bolt. The loose end is looped through the bolt and wrapped around the wire itself (Fig. 1 & two) The tension wire loop is 'sandwiched' in the brace band. Bottom tension wire is installed on the aforementioned side of the posts every bit the chain link fabric (Fig. 4.) In one case concatenation link is stretched, the bottom tension wire will be 'sandwiched' between line/ intermediate posts and the concatenation link cloth (Fig. ten). If used every bit a top wire, thread tension wire through loop caps and connect at each terminal mail service.

Figure v

Figure 6

Effigy 7

Effigy 8

Tension wire is most commonly stretched using a come-a-long and wire grip. Do non wrap the cable of the come up-a-long around the post (Fig. v). This activity done repetitively will cause the cable to fray and exist destroyed. Instead a 'sling' may exist made of rope or cable to wrap around the stretch post (Fig. 6). Release and pull out 6-ten' anxiety of cable from the come-along. The length of cablevision to pull out volition depend on the length of stretch of tension wire. Hook a cable puller to the ratchet terminate of the come up-a-long. Secure tension wire to cable puller (Fig. seven). Crank the handle of the come-a-long until the tension wire is tight (Fig. 7 & 9). Do not tighten likewise much or post damage or physical injury may occur.

Figure 9

Figure 10

Figure xi

Figure 12

With the come-a-long cranked tight, bend the tension wire where it would loop into the nut and bolt. Side by side, cut 6-8" past this bend with bolt cutters. Be careful as both ends of the wire volition 'whip' from the tension and can be dangerous. Fish the looped end of wire through the nut and bolt and wrap equally before. Release come-a-long; echo process for other runs of fence. Notation: Short lengths, approx. 12' and less, are difficult to do using a come up-a-long. These are often only done by manus. The tension wire naturally has crimps in it. With the use of pliers in their open position, these crimps can be crimped further causing the wire to tighten (Fig. eight). Be certain to crimp throughout the length for uniform appearance.

Figure thirteen

Figure xiv

Figure 15

Figure 16

Once tension wire is installed, the concatenation link cloth may exist stretched. Concatenation link is installed to terminal posts using tension bars, tension bands, and basics and bolts. Often ane end is installed with the gyre upright for ease (Fig. xiv). The roll may then be laid down flat of the ground and rolled to other terminate. Additional rolls may exist added easily and the weaving is easily done on the flat ground. Chain link is stretched with a come-a-long and spreader bar for longer stretches (xx' or more than). A pul-jak is used for shorter stretches (20' or less) (Fig 15). As tension bands are installed an equal distance apart, usually the bottom brace ring holding the tension wire may be adjusted so that the tension wire is centered on the bottom diamond of the fabric. The height rail, line posts are tied last. Squealer rings are installed to secure the tension wire to the chain link fabric using hog ring pliers.

Stretching Chain Link Cloth:

Hook-up chain link fence to one terminal postal service and curlicue information technology out towards other end.

Information technology is best to lay chain link rolls downward flat for longer stretches.

Stretch chain link fence using a stretch bar, come-a-long, and a tension bar.

A come up-a-long is required for longer stretches of fence.

A pul-jak is the ideal tool for brusk stretches of fence.

Remove a weave to 'cutting' the fabric to the correct length.

Claw up tension bands using five/sixteen" x one-ane/4" basics and bolts. Adjust height earlier tightening.

View of debate from inside: Notice flat side of tension band faces out, nut is on within.

Tentatively adjust height earlier tightening nuts and bolts.

Be sure to center pinnacle chain link diamond on runway prior to tying.

The finished chain link fence.

Step ane - Starting at one cease of a line of debate, roll chain link out on the exterior of the enclosed area or the side yous previously take chosen.

Step 2 - Roll out another ringlet, if more is needed to achieve the next end postal service. Concatenation link is stretched in i continuous length of woven chain link from end mail to stop mail service.

Step 3 - 'Weave' concatenation link rolls together. This can exist a trivial tricky, if never done before, and requires some explanation.

Each weave is continuous from the top to the bottom along the vertical or acme of the roll. If you follow the strand, starting at the top, you volition see that it zig-zags back and forth to the lesser. Information technology starts and ends with either a 'knuckled' or a 'twisted' terminate.

To remove a weave, unbend the terminate of the weave 'knuckle' straight. Unbend the side by side weave that is knuckled to it. If it has a twisted cease, simply untwist the two weaves until they tin can exist separated.

Follow the weave to the other finish as information technology zig-zags back and forth and untwist or unknuckle the contrary finish. Be sure you lot follow carefully, so y'all undo the proper weave.

At the pinnacle of the argue or the bottom, spin the weave in a counter-clockwise direction, as if to unscrew information technology from the roll. Most newly manufactured chain link spins out counter-clockwise, whereas some chain link manufactured years ago spins out clockwise. Go along spinning and you will see the other cease unweaving from it'due south adjacent weaves. If you are having difficulty, y'all may have disconnected the wrong weaves at the contrary terminate. Also cheque that you accept aptitude the far end directly or it will snag as you try to spin it. Another problem that may occur is the chain link is stretched to tight; requite yourself some slack.

The procedure for weaving ii rolls together is just the reverse except it can exist tricky getting started. It is easiest to weave two rolls together when they lay apartment on the basis, however rolls may exist wove together in the upright position too.

To kickoff weaving: Concatenation link forms squares or 'diamonds' as they are frequently called. You must match two sections or rolls together earlier you get-go weaving in such a way that one roll has a full diamond and the other curl has a half diamond. This friction match will be at the peak and bottom of the rolls. When you lot add a weave, you will cease up with a total diamond and 2 ends to knuckle or twist together.

Many rolls of concatenation link will take a loose wire in the roll. Utilize this to piece two rolls together or remove one wire from 1 of the rolls to splice with. Spin the unmarried weave into the first full diamond. Spin information technology through the next full diamond of the other coil. Continue spinning and make sure that the weave end goes through each full diamond on each whorl in each revolution.

If yous have problem, it could be from i or more than of the following reasons: Your concatenation link is also tight; give some slack. You missed a diamond somewhere; unweave and endeavor again. Lastly. you may have mismatched rolls that came from different manufacturers or the rolls take different mesh sizes; count the number of full diamonds in each ringlet, they should match in number and size.

After you have successfully woven the two rolls together, twist or re-knuckle the ends together. If you have no counter weave to spike to, y'all started with either two half diamonds on each roll or two full diamonds on each roll. Take it apart and attempt again. Sometimes you accept to flip the i roll over (most have a half diamond at ane stop and a full diamond at the other) or remove a weave from one roll to create a starting one-half or full diamond.

Pace iv - After rolling out the chain link and weaving the rolls together, 'hookup' ane end. Infinite the tension bands evenly as illustrated higher up (Fig. F51). Make sure the nuts are on the inside of the fence so they can not be removed from outside the enclosure.

If yous accept a sharp incline budgeted a terminal post, the textile must be cut on the stop. This is called a bias cut. Read More: How to Bias Cut Concatenation Link.

Step 5 - Pull the chain link tight by hand to the other end. You may stand the chain link and lean it against the posts or leave it on the footing and lean it upwards every bit you stretch the cloth later. Mostly the later is easier and better on long stretches.

Step 6 - Claw up stretch tools equally illustrated on inside of debate (Fig. F51). Slide a tension bar ten-12' away vertical in concatenation link fabric; claw stretch bar to it on within.

Footstep 7 - Brand sure the come-a-long hook faces away from the material or it may get caught in the diamonds.

Pace 8 - Tighten the come-a-long slowly. Check that the fabric is non getting caught on posts, tree roots, or other obstacles.

Step 9 - 'Wearing apparel' the fabric every bit you tighten it. 'Dressing' involves straightening the fabric diamonds then they run truthful. This is vital for heavier estimate fabrics. Some spots will be higher than others as you lot sight down the top. Lift the fabric in the low spots. This must be done before the fabric gets too tight. In one case information technology is tight, lilliputian tin can be done to straighten the material. Some fabric dresses easily, some does not. If the fabric does non dress up properly, you can e'er loosen the come up-a-long and try once again. Bank check top and bottom diamonds for whatsoever wires that may bind out of proper shape. Lift and milk shake fabric to assure an even tension throughout roll(due south).

Stride x - The fabric is stretched sufficiently when you can't squeeze the diamonds together with i paw. Do not over stretch or post damage will occur. The top of the contend should 'snap' back to the posts when pulled out a little.

Step 11 - Manus stretch the small section of chain link left between the come-a-long and terminal post by hand. Remove a weave to 'cutting' the fabric to proper length. Slide the tension bar into the mesh and make your last hookup. In one case all bolts are in place, remove the stretching tools.

Tying Off The Fence:

Step 1 - Install tie wires onto peak runway beginning to establish the height of the fence. The top diamond of concatenation link should be centered on the peak rails.

Step 2 - Infinite tie wires evenly and no more than ii' autonomously.

Step 3 - Tie line posts last. Employ the aforementioned number of tie wires per line mail every bit tension bands per terminal. This quantity is a minimum of 1 per pes.

Installing Concatenation Link Gates:

There are many different types of hinges and latches on the market today for use with concatenation link gates. Nearly are self-explanatory and practice not include a prepare of installation instructions. Installation instructions unremarkably accompany the more complicated hinges and latches.

Single Swing Gates:

Basic Swing Gate Hardware

Step 1 - Install female hinges on gates using nuts and bolts. Again, nuts should be installed on the inside of the enclosure. Space them the maximum distance autonomously as possible.

Step 2 - Hold gate in opening and marker the location of male person hinges. Indicate the male swivel on the bottom up and the one on top down.

Step 3 - Install bottom and height male hinge with bolts. Tighten bottom swivel snug, but leave acme hinge loose.

Step 4 - Place gate on bottom hinge and lower top male hinge into female swivel.

Step 5 - If the infinite under the gate is acceptable. Tighten top male swivel snug.

Step 6 - Examination swing the gate to see if information technology will miss the ground. Suit as needed.

Step 7 - Tighten all hinge bolts. Practice not over tighten.

Step 8 - Install the latch at a convenient height (basics within).

Double Swing Gates:

In the case of double swing gates, you will desire to install the gate closest to the ground first, unless the ground is perfectly level. Hang 2d gate level to the first. Although you lot may 'pace' the gates for a tight fit to the footing, information technology looks best to install them level to one another.

Follow Steps 1-seven from to a higher place to hang the gates. After that is washed, follow the steps below to latch the gates together.

Drop Rod & Center Stops

Footstep eight - Install the double gate drop rod/latch assembly.

Step nine - Install center terminate for double swing gate. Close the double gate, making certain the two leaves are lined up (straight w/ fence line). Mark the ground where the eye end needs to exist installed. You lot may simply utilize a cut-off piece of pipe as a center stop by driving it into the basis. Proceed slowly, checking the gate to brand certain you lot are driving the pipe straight. Yous may as well apply a prefabricated heart cease and cement information technology for a better appearance. If the centre end is in a concrete drive, just drill a hole in the concrete larger than the drib rod bore. Be sure to drill clear through the concrete drive to allow h2o to drain. Always make a much larger hole (or pipe size) than the diameter of the driblet rod to allow for gate sag, posts shifting, ice and other factors.

Optional Step - Install Gate Holdbacks if desired. Open gate(s) to the desired 'open up' position. Cement or drive a 2" O.D. post a couple inches beyond this point. Install holdback at correct height using U-bolts provided.

Final Step - Install all mail service caps.

Slide Gates:

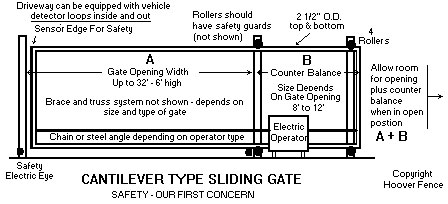

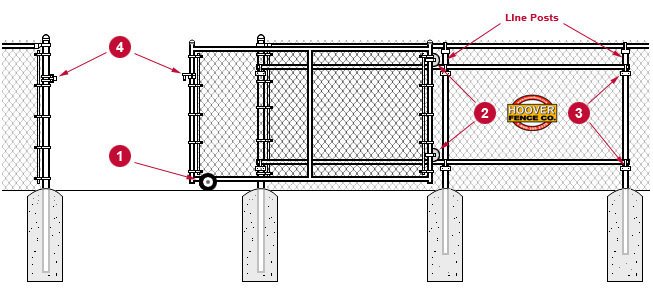

Chain Link Cantilever Gate

Chain Link Rolling Gate

Read More than: Chain Link Cantilever Gate System Overview | Chain Link Cantilever Installation Manual | Chain Link Rolling Gate Organization Overview

Source: https://www.hooverfence.com/chain-link-fence-installation-manual

Posted by: tapperbefrele.blogspot.com

0 Response to "How To Install Chain Wire Fence"

Post a Comment